MORE PROFITABLE PROCESSING

Optimar has played a major role in designing and producing the automatic and robotic systems that have made fish processing easier, faster, safer, cleaner and more profitable.

Our work has been largely behind-the-scenes but we are well-satisfied knowing that we have helped transform an entire industry from total dependence on manual labor to one that is sleek, efficient, automated and globally competitive.

Other sectors of the food processing industry have quickly discovered that the innovative approaches Optimar developed for handling fish are just as applicable for them.

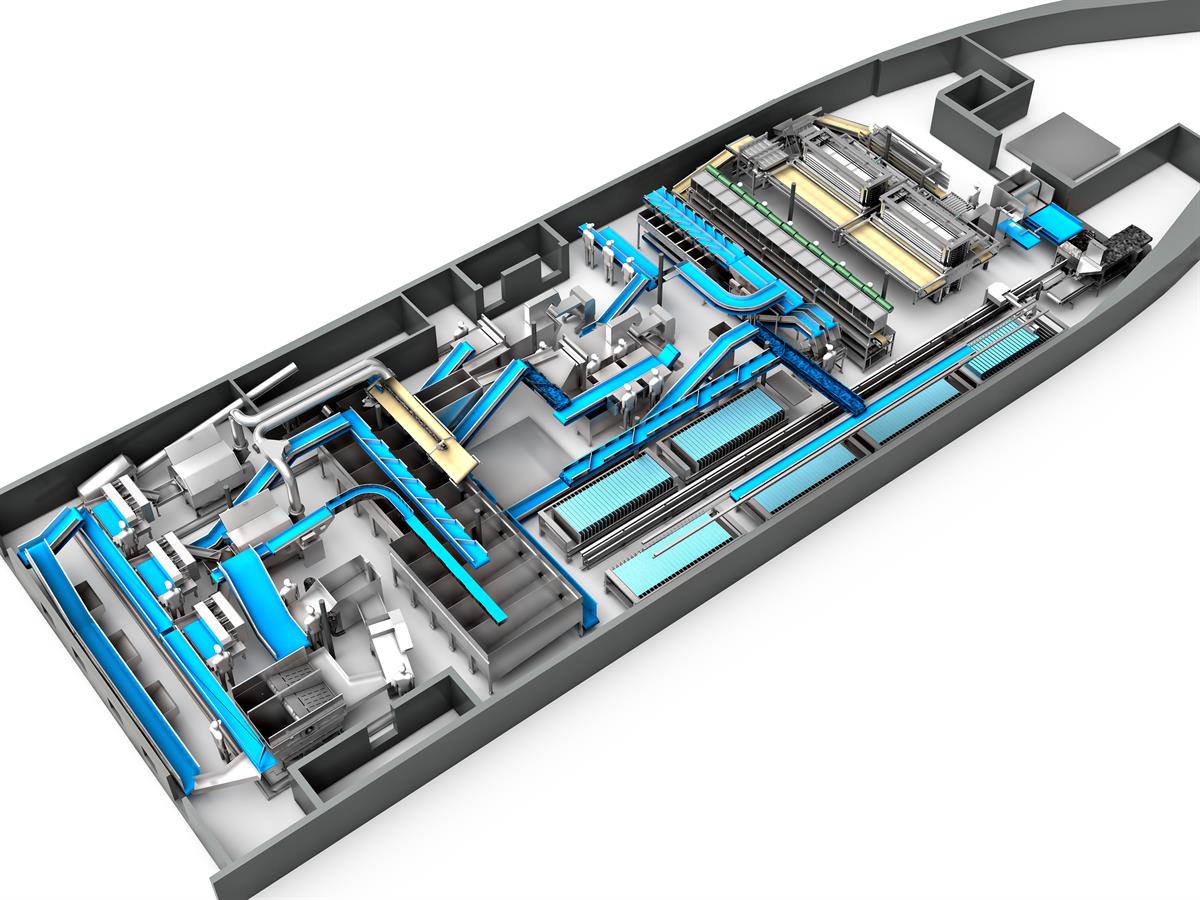

SUCCEED IN EXTREME CONDITIONS

If we can make it here, we can help you make it anywhere! We always have a plan, and even a backup plan too...

Today, it is vital for our customers to have equipment that is reliable and a processing facility that saves time, energy and money. We have proven that Optimar’s automated systems are so robust we can meet these needs in the most extreme conditions on earth where every minute counts and downtime is not an option.

We have succeeded when

- reliability is crucial

- support is far away

- volums peak in short intervals

- automatic solutions are needed

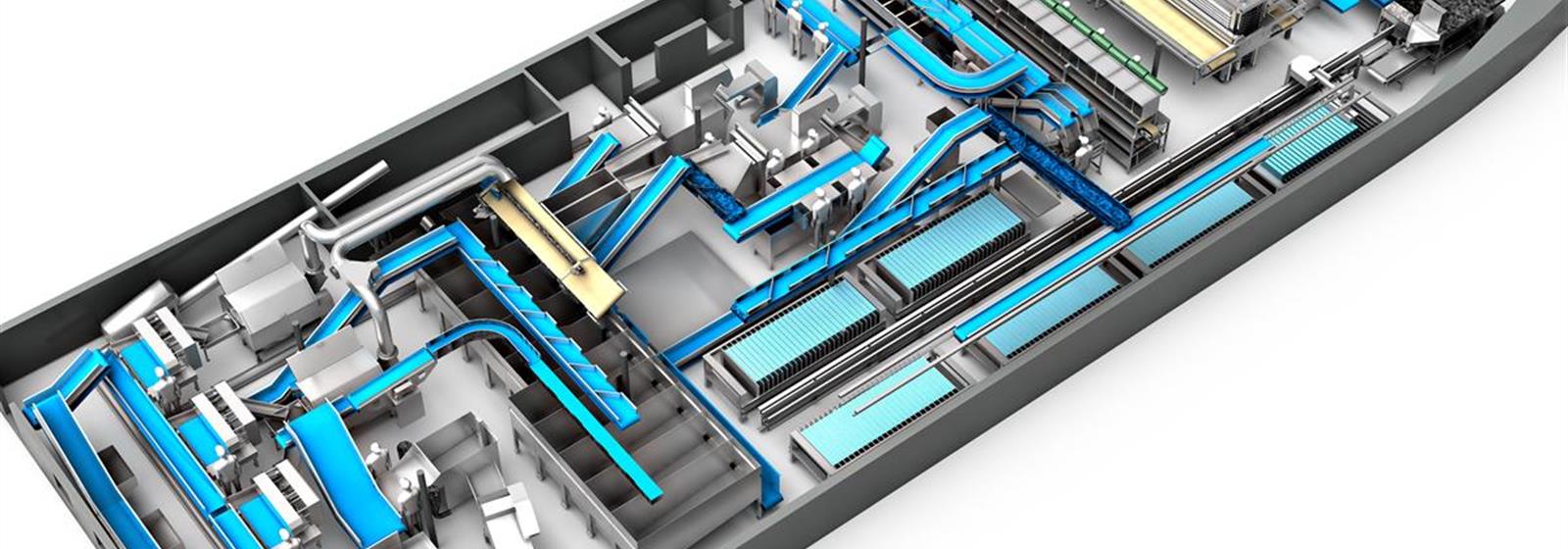

MAKE THE MOST OF EVERY METER - AND MAN

Reduce the production area, reduce the labor force, reduce manual heavy-load handling, and maximize use of space available.

Optimar works closely with you to understand the unique problems you face. Our teams of experts in design and logistics, in automation and robotics, in installation and service will assess your needs and provide solutions that improve the effciency – and proftability – of the processing line.

On land or at sea, Optimar can help you:

- Reduce the production area

- Reduce the labor force

- Reduce manual heavy-lifting

- Maximize use of space available

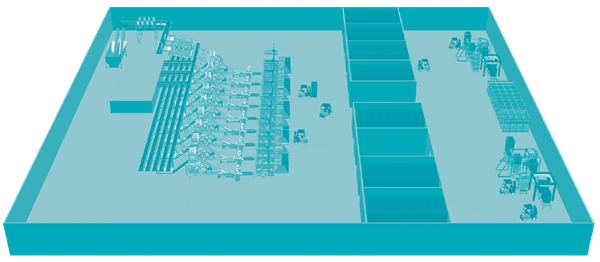

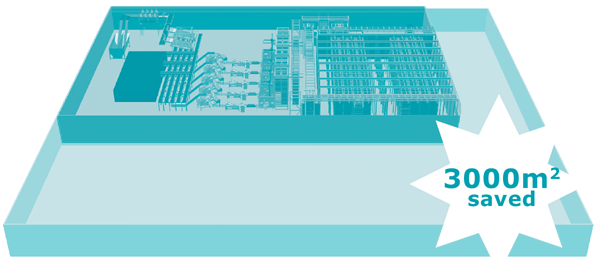

SAVE SPACE ON LAND TOO!

Optimar's fully-automated solutions reduces area required by 50% or more.

MANY RETURNS ON YOUR INVESTMENT

Pelagic blast-freezing plant producing 500 tons per day

Traditional solution

- Requires forklifts and drivers

- Wastes energy by repeatedly opening and closing entrance and exit doors

- Work areas must be heated or cooled, and cleaned

Optimar's fully automated solution

- Reduces area required by 50% or more

- Replaces forklifts and drivers with automatic handling and conveyor systems

- increasing safety

- reducing labor force

- reducing vehicle maintenance and repair costs

- eliminating poor-driving damaage to surroundings

- conserving energy by reducing in/out access points

- Requires 20% less installed compressor capacity

PROTECT YOUR INVESTMENT

Optimar makes sure you are well-equipped to handle any current trend or future reality.

You can’t afford the risk

Optimar systems are modular. This makes it possible, efficient and cost-effective to integrate standard or customized equipment that may already be part of your processing facility.

Optimar makes sure its systems have the flexibility to adjust to your needs as they change. It also makes sure they can adapt to new technologies as they become available and proven.

Optimar solutions are realistic, practical and tailored just for you. They are solutions you can’t afford not to try if you want to ensure your competitive edge today, and tomorrow.

- Teams of OptiService technicians are on call 24/7

- Spare parts are in stock in key locations around the world

- Back-up plans are always in place

AROUND THE WORLD - AROUND THE CLOCK

Optimar is always nearby to provide sales support, service and training. Worldwide presence 24/7.

A world wide presence

With its roots strongly planted in the fishing industry, Optimar is well-known in regions of the world where fishing is a way of life. We have representatives or agents in strategic locations where we have had primary design and fabrication responsibilities for over 600 installations.Our well-established resources in local markets throughout the world, together with the Internet that now connects even the most remote areas, means Optimar is always nearby to provide sales support, service and training.